Table of Contents

Introduction

Accurately measuring HIWIN linear guide rails is essential for both new installations and replacement projects. Accurate measurements ensures optimal performance and compatibility. Here’s a step-by-step guide on how to measure your HIWIN linear guide rail correctly. At the conclusion of this post, you will find convenient links for purchasing HIWIN Linear Guide Rail for your own projects.

Key Dimensions to Measure

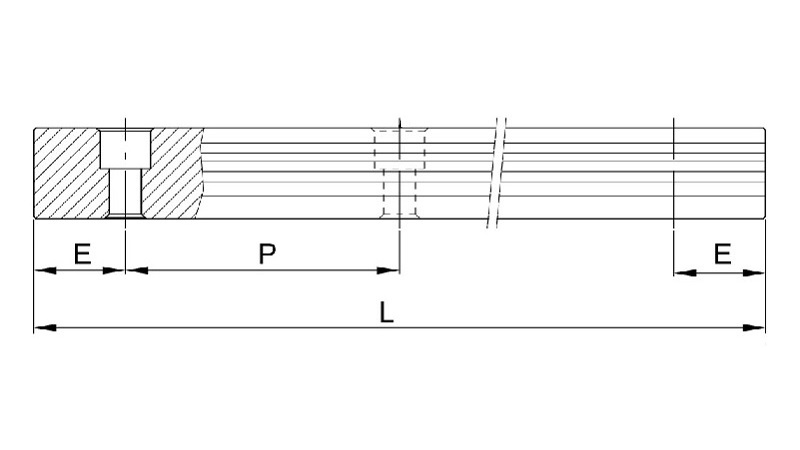

There are 4 key dimensions to account for when measuring HIWIN Linear Guide Rail: Length (L), Pitch (P), the Distance from the End of the Rail to the Center of the First Mounting Hole (E), and the Number of Mounting Holes (N).

- Length (L)

- Definition: The overall length of the rail specified to facilitate the function of the machine or equipment.

- Measurement: Measure the full length of the rail from one end to the other.

- Note: Most machines and equipment require Linear Guide Rails to be a specified length with little room for variance.

- Pitch (P)

- Definition: The distance between the centers of two adjacent mounting holes.

- Measurement: Measure the distance between the centers of two consecutive mounting holes. For easier measuring, you may also measure from the same edge of each hole.

- Note: HIWIN has determined this dimension as the ideal distance between mounting screws for consistent rigidity, strength, and stability. This measurement may help identify an unknown rail and determine compatibility when converting to HIWIN rail from another manufacturer.

- Distance from the End of the Rail to the Center of the First Mounting Hole (E)

- Definition: The distance from the end of the rail to the center of the first mounting hole.

- Measurement: Measure from the end of the rail to the center of the first mounting hole.

- Note: Commonly referred to as the “E Dimension” or End Dimension, this dimension ensures that the mounting holes align properly with the machine bed or other mounting surface. STOVIL cuts all replacement rails to HIWIN specifications of within 0.5 mm of the specified rail “E Dimension”. This is probably the most important dimension to measure accurately, as any variance impacts overall length.

- Number of Mounting Holes (N)

- Definition: The total number of mounting holes along the rail.

- Measurement: Count the number of mounting holes along the length of the rail.

- Note: This provides the total points of attachment, contributing to the rail’s stability and load distribution.

Tools for Measuring Linear Guide Rail

- STOVIL suggests using Mitutoyo Calipers for precise measurements of shorter dimensions like Pitch (P) and the “E Dimension”. You can also use calipers to measure the overall length of very short rail.

- You can use any metric tape measure for measuring Length and Pitch.

Measuring for New Installations

- Determine the Required Length (L): Verify that the length of the installation surface can accommodate the overall length of the rail. There may be subtle and impactful differences between the engineering plans and the machine when built.

- Verify the Pitch (P): Check the spacing of the mounting holes on the machine or equipment and match it with the rail.

- Check the End Distance (E): Always check for clearance at the ends of where the role mounts. For machines with tight tolerances, an overage on the E Dimension cut may result in an obstruction.

- Count the Mounting Holes (N): Ensure that the number of mounting holes on the machine matches the number of mounting holes on the rail. Two rails of the same length may produce two different counts of mounting holes.

Important Note When Specifying an E Dimension

- Distance from the End of the Rail to the Center of the First Mounting Hole (E) Should Be Less Than Half of the Pitch (P):

- Note: Keeping the distance E less than half of the pitch P is important. This ensures that the rail securely attaches at the ends and prevents any overhang or unsupported sections. This is crucial for the stability of the rail. This placement minimizes deflection and enhances the rigidity of the installation, providing better accuracy and load-bearing capacity.

Measuring for Replacement Rails

- Measure the Existing Rail Length (L): Measure the length of the existing rail to ensure the new rail matches perfectly.

- Confirm the Pitch (P): Measure the pitch on the existing rail and match it with the new one. This will help if the model of the existing rail is unknown or when switching to a different model.

- Measure the End Distance (E): Verify that the E Dimension cuts on the new rail are within 0.5 mm of the existing rail.

- Count and Match Mounting Holes (N): Verify that the new rail has the same number of mounting holes as the existing rail. Again, note that it is possible for two rails of the same length to have two different number of mounting holes.

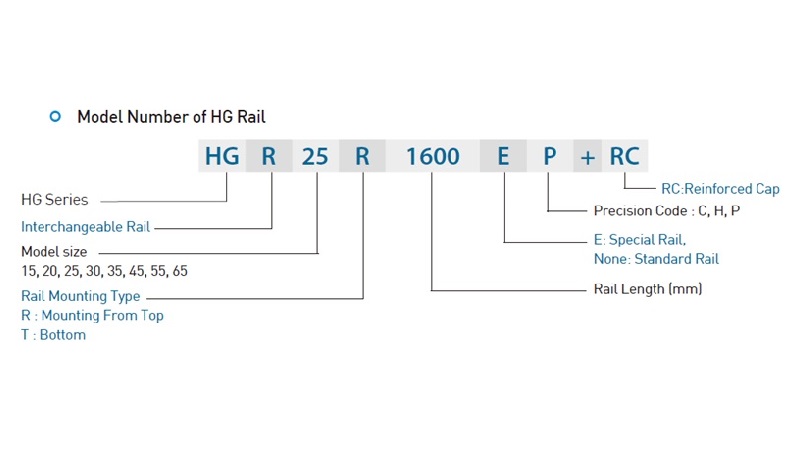

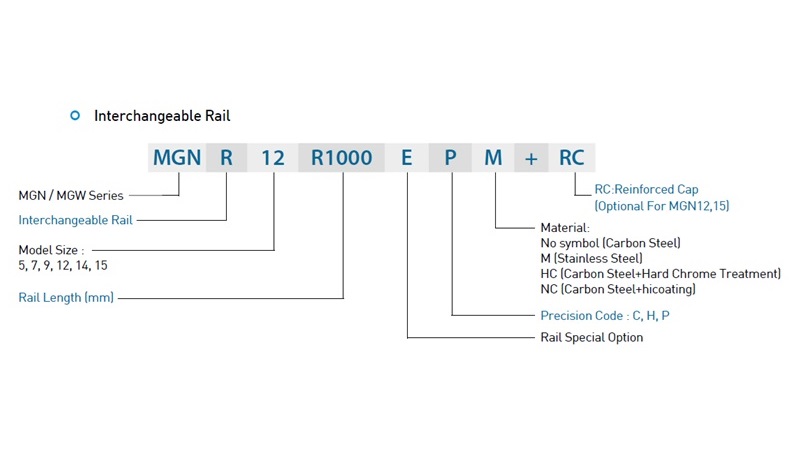

How-to Read a HIWIN Interchangeable Rail Model Number

- Model Number paradigm for MG Series (both MGN and MGW rails):

- REMINDER: HIWIN rail model numbers are always in millimeters (mm).

Ordering Linear Guide Rail

STOVIL offers HIWIN Linear Guide Rail with either custom “E Dimensions” or standard “E Dimensions”. STOVIL refers to these two options as “Cut-to-Order Rail” and “Standard Length Rail”, respectively. You may also order rail with standard “E Dimensions” via the “Cut-to-Order Rail” category of listings as well.

Conclusion

Follow these steps to ensure your HIWIN linear guide rail fits perfectly and performs well over the lifetime of your machine. Accurate measurements contribute to the efficiency, stability, and longevity of your machinery.