In industrial settings, Armoloy Thin Dense Chrome (TDC) coating stands out as a solution for improving durability, performance, and precision. Especially suited for linear motion systems, TDC delivers exceptional benefits that extend the lifespan and efficiency of linear guideway components.

Characteristics of Armoloy TDC Coating

Armoloy Thin Dense Chrome (TDC) is a specialized chrome coating applied in thin, uniform layers to metal surfaces such as linear guide rail and bearing blocks. Key characteristics include:

- Base Metal: Linear guideways typically use alloy steel, which serves as a perfect base for applying Armoloy TDC coating.

- Coating Application: After cleaning and surface preparation, the material undergoes electroplating in a specialized bath with an electric current to ensure strong adhesion.

- Texture: At the microscopic level, TDC coating has a cracked and fissured texture that contributes to its lubricating and wear-resistant properties.

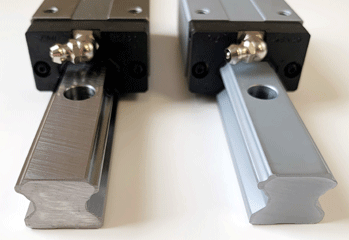

- Appearance: Components with Armoloy TDC coating feature a silver-gray satin finish.

These characteristics make Armoloy TDC coatings ideal for linear guideway blocks and rails.

Benefits of Armoloy TDC on Linear Guideways

When applied to linear guideways, Armoloy TDC coatings offer significant benefits that enhance performance and longevity:

- Friction Reduction: Enables smooth and precise motion, improving overall system efficiency.

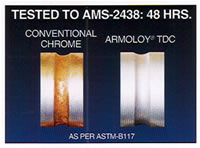

- Corrosion Resistance: Protects components from harsh or chemically exposed environments.

- Extended Service Life: Minimizes wear, increases reliability, and reduces maintenance downtime.

- Dimensional Integrity: Ultra-thin coating preserves fit and alignment for precision operation.

These benefits make TDC coatings invaluable for industries such as robotics, manufacturing, and automation.

Applications of TDC-Coated Linear Guideways

The exceptional properties of Armoloy TDC coatings make them indispensable across various industries that demand precision, durability, and resistance to challenging environments:

- Robotics and Automation: Ensures smooth motion and minimal maintenance for robotic arms and automated systems.

- Manufacturing: Enhances durability in CNC machines, assembly lines, and production equipment.

- Medical Devices: Supports precision movement in diagnostic and surgical equipment.

- Aerospace: Delivers corrosion-resistant linear components for aircraft and space systems.

- Food Processing: Provides smooth, hygienic surfaces ideal for clean and sterile environments.

From industrial manufacturing to advanced robotics, Armoloy TDC coatings optimize linear motion performance to fulfill the requirements your project demands.

Impact on Preload in Linear Guideways

While Armoloy TDC coatings are applied in ultra-thin layers, the added thickness (starting at 0.000050 inches) can subtly affect preload by altering the fit between the rail and block. To compensate, selecting a block with a lighter preload may be necessary. Proper planning during the engineering or design phases ensures system performance remains uncompromised, allowing you to benefit fully from TDC’s friction reduction and durability.

Request a Quote and Experience the STOVIL Advantage

Upgrade your linear motion systems with Armoloy TDC coatings for unmatched durability, precision, and performance. Contact sales@stovil.com today to request a quote or learn more about how TDC coatings can enhance your operations. STOVIL handles the logistics and communication to streamline the process for you, the customer.